Hydraulic Accessories: Essential Components For Efficient Systems

02 September 2025

Hydraulic Accessories: Essential Components For Efficient Systems

Key Hydraulic Accessories and Their Functions

1. Filters

Hydraulic systems require clean oil for smooth operation. Filters remove contaminants such as dirt, metal particles, and moisture, protecting critical components like pumps, valves, and cylinders from damage.

2. Pressure Gauges

Pressure gauges monitor the system's pressure levels, ensuring they remain within safe operating ranges. This accessory is vital for maintaining system stability and diagnosing potential issues.

3. Hoses and Fittings

Hydraulic hoses and fittings connect various components, facilitating the flow of hydraulic fluid. High-quality hoses and leak-proof fittings are essential to prevent fluid loss and maintain system efficiency.

4. Reservoirs

Hydraulic reservoirs store the fluid used by the system. They also play a role in cooling, de-aeration, and contaminant separation, ensuring the hydraulic fluid is in optimal condition.

5. Accumulators

Accumulators store energy in the form of pressurized fluid, which can be released during peak demand or as a backup in case of system failure. They also help in dampening pressure surges.

6. Heat Exchangers

Hydraulic systems generate heat during operation, and excessive heat can reduce performance and damage components. Heat exchangers regulate temperature by dissipating excess heat, keeping the system within safe operating conditions.

7. Breathers

Breathers allow air exchange in the reservoir while preventing contaminants like dust and moisture from entering the hydraulic system.

8. Manifolds

Manifolds distribute hydraulic fluid from a single source to multiple components. They simplify system design, reduce leakage points, and improve space efficiency.

9. Clamps and Mounting Accessories

Properly securing hoses and pipes is crucial to prevent vibrations, wear, and potential damage. Clamps and mounting accessories ensure that components are held firmly in place.

Benefits of Hydraulic Accessories

-

Enhanced System Efficiency: Accessories like filters and heat exchangers maintain optimal fluid quality and temperature, improving the overall efficiency of the hydraulic system.

-

Increased Safety: Components such as pressure gauges and accumulators help monitor and control the system, reducing the risk of accidents and failures.

-

Extended Component Lifespan: By preventing contaminants and overheating, hydraulic accessories minimize wear and tear, extending the life of primary components like pumps and valves.

-

Improved Reliability: Well-maintained accessories ensure consistent system performance, reducing downtime and maintenance costs.

Applications of Hydraulic Accessories

Hydraulic accessories are widely used across industries, including:

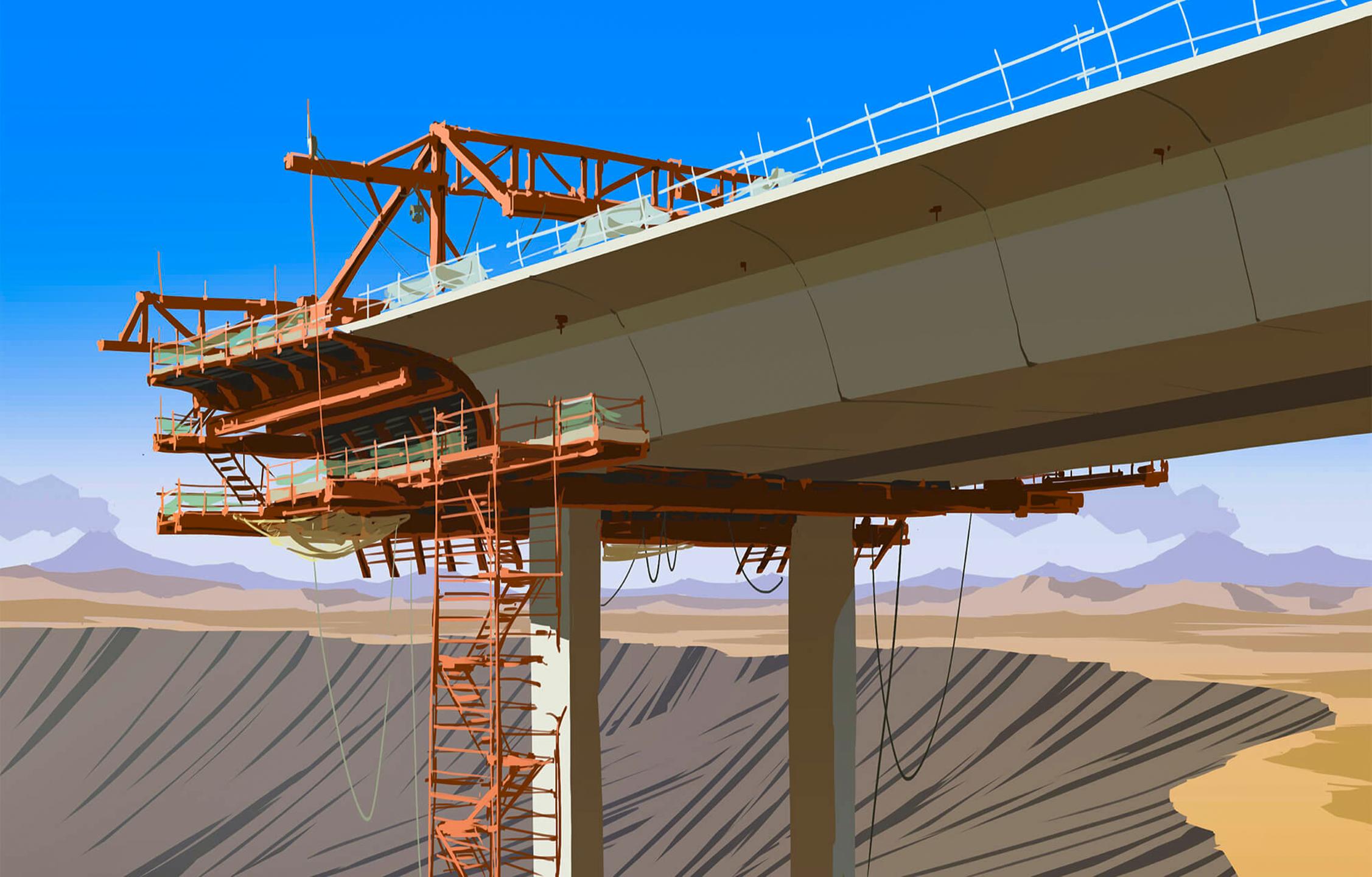

- Construction: Supporting heavy machinery like excavators and cranes.

- Manufacturing: Enhancing the precision and efficiency of assembly lines and presses.

- Automotive: Powering hydraulic braking and steering systems.

- Agriculture: Facilitating equipment such as tractors and harvesters.

- Aerospace: Assisting in aircraft landing gear and control systems.